ABOUT US

ABOUT US

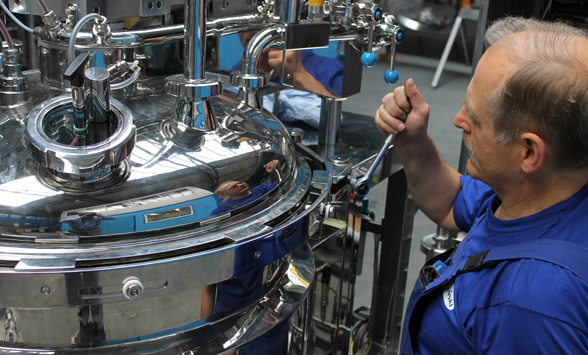

The company has been designing and manufacturing equipment for cosmetic and pharmaceutical products for more than thirty years.

Knowledge of the branch and experience acquired during realization of numerous technological lines have resulted in achievement of important position in Europe as a process machinery supplier for cosmetic industry. Currently, export makes a half of our total production. You can find in our offer the complete solutions for production of skincare and decorative cosmetics in accordance with FDA directives and GMP guidelines.

HISTORY

All started in the eighties of last century, when the name of Urliński was not widely known in cosmetic industry. In 1984, the owner – Andrzej Urliński, started activity connected with process machinery production, acquiring experience through cooperation with the largest cosmetic company those years in Poland. Exact look at technological problems during production of cosmetics helped to find the most effective solutions.

Thanks to innovative ideas and engagement in improvement of mixing and homogenization, Urlinski company quickly became known on Polish and European market even without support of authorities or sometimes with their opposition to private business.

Fortunately those years passed and currently Urliński company is one of the world leaders in the branch of process machinery for pharmaceutical and cosmetic industry.

STANDARDS

Our equipment meets high pharmaceutical standards of FDA rules and is supplied together with IQ/QQ validation documentation. We specialize in production of first-class quality homogenizing mixers based on innovative solutions and advanced technology. Our skilled constructors take care about details of the project and thanks to our certified workers from production line our devises are sustainable and precise so the whole process can be perfectly repetitive which complies with special requirements of pharmaceutical and cosmetic products.

OFFER

- All mixers are designed and fabricated in conformity with “scale-up” procedure allowing technologists to transfer the formula from laboratory devices to industrial ones.

- We offer custom projects for clients’ individual requests. Depending on the technology and product requirements, we apply operational panel control from manual to fully automated including data recording.

- For client’s request we carry out DQ, IQ and OQ qualification for validation of technological process

- We offer complex solutions – full production lines according to GMP guidelines as well as technological support and stuff training

CONTACT US !

FOR MORE INFORMATION PLEASE CALL US OR SEND US YOUR MESSAGE USING OUR CONTACT FORM!

![]() +48 22 514 05 00

+48 22 514 05 00

PARTNERS: